UHP Graphite Electrodes

- 1shanchuncarbon

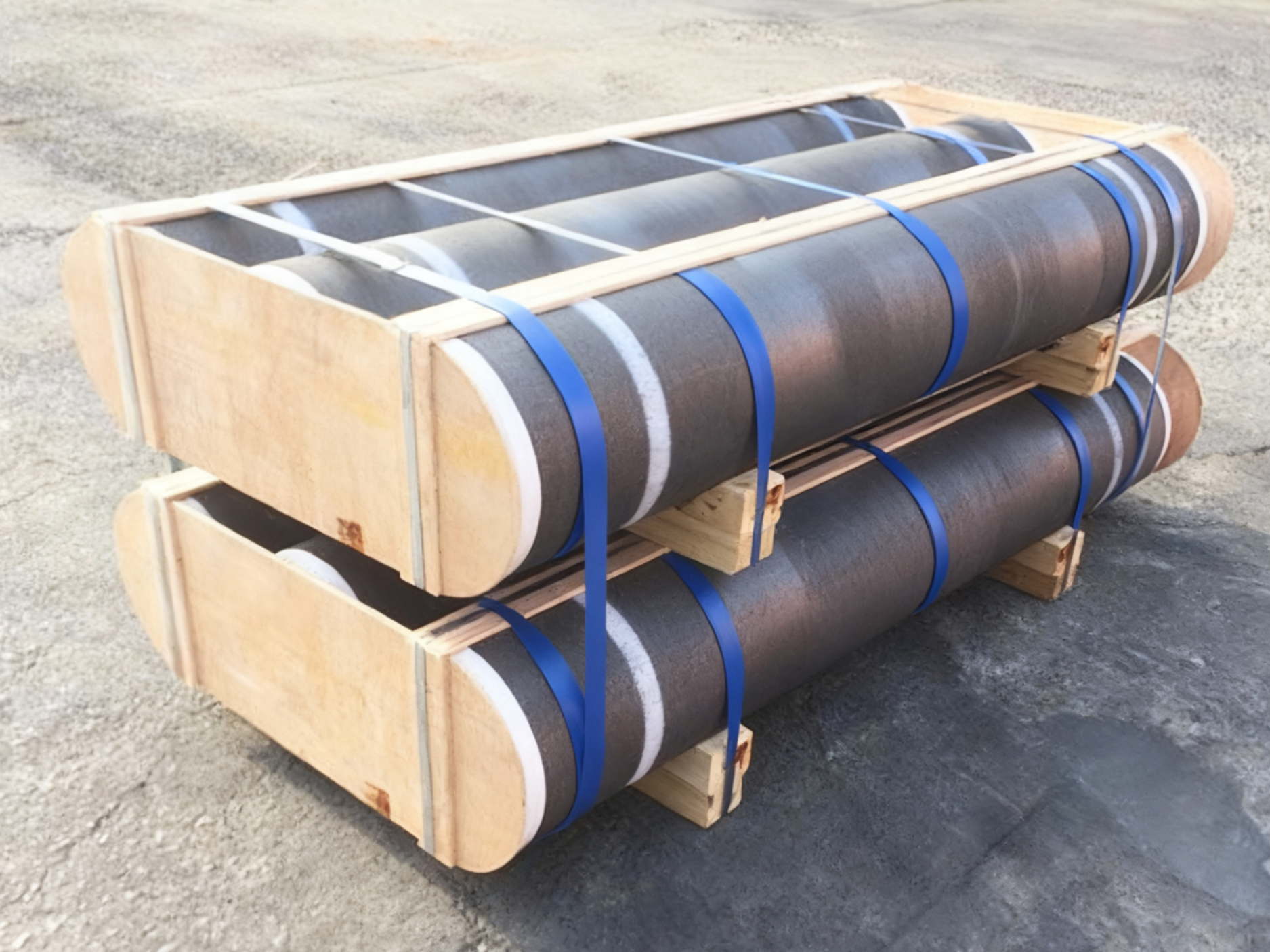

UHP Graphite Electrodes

UHP graphite electrodes are engineered for top-tier performance in Electric Arc Furnace (EAF) and Ladle Furnace (LF) steelmaking. Manufactured from premium needle coke through ultra-high temperature graphitization, they feature:

- Excellent electrical conductivity

- High mechanical strength

- Low electrode consumption

- Outstanding thermal shock resistance

All ShanChun® Carbon electrodes are supplied with pre-set graphite nipples (4TPI / 3TPI) for secure connection and stable current transmission.

About ShanChun® Carbon

ShanChun® Carbon specializes in the production and export of graphite electrodes for global steel mills and foundries. We focus on enhancing value for steel mills by lowering the electrode cost per ton of steel. Our manufacturing capability covers:

- UHP, HP, RP graphite electrodes

- Diameters: 200mm – 700mm

- Nipples matching 3TPI / 4TPI / Internal taper thread

- Annual production capacity: 30,000+ tons

We ensure quality through strict standards:

| Control Aspect | Standard / Benefit |

|---|---|

| Raw materials | 100% needle coke from China & global suppliers |

| Production | Full-process automated control lines |

| Testing | Resistivity / Density / NDT flaw detection |

| Delivery | Direct shipments to over 18 countries |

Raw Materials

Our UHP electrodes are produced using strictly selected carbon materials:

- Petroleum Needle Coke → Needle Coke Raw Material

- Coal Tar Pitch Binder → Coal Tar Pitch for Graphite Electrode

- Artificial Graphite Scrap (Recarburizer) → Graphite Scrap Material

- Special Oxidation Inhibitors → Anti-oxidation Additives

Raw materials are tested before use to ensure crystal structure integrity and minimum impurity content. Feature of needle coke used in UHP:

| Property | Specification |

|---|---|

| Sulfur Content | ≤ 0.5% |

| True Density | ≥ 2.13 g/cm³ |

| Low ash, low thermal expansion | High conductivity & durability |

Production Process of UHP Graphite electrodes

Core processes in UHP electrode manufacturing:

➡ Graphite Electrode Production Process

1️⃣ Raw Material Calcination

2️⃣ Crushing, Milling & Sieving

3️⃣ Mixing with Pitch → Binder Formulation Control

4️⃣ High-pressure Forming

5️⃣ First Baking

6️⃣ Impregnation Treatment → Electrode Impregnation Process

7️⃣ Re-baking

8️⃣ High-temperature Graphitization at 3000°C

9️⃣ CNC Machining → Electrode Machining Control

🔟 Final Inspection (Resistivity, Density, Strength, NDT)

Why Choose ShanChun® Carbon UHP Electrodes?

- 100% Needle Coke Raw Material

- High Mechanical Strength — low risk of breakage

- Ultra-low Electrical Resistivity

- Low Unit Consumption → Cost reduction per ton of steel

- Strong Thermal Shock Resistance

- Precision Thread Machining

- Global Supply Capability

Application Fields

- Electric Arc Furnace (EAF) Steelmaking

- DC/AC Arc Furnace

- LF Refining Furnace

- Submerged Arc Furnace

Technical Service Support

ShanChun® Carbon ensure stable electrode performance in real steelmaking environments. we provide:

- On-site Installation & Connection Guidance

- Breakage Analysis & Troubleshooting

- Furnace Consumption Optimization Solutions

📩 Contact ShanChun® Carbon for a Quote

Boost your steelmaking efficiency with high-performance UHP graphite electrodes.

📧 Email: info@shanchuncarbon.com

🌍 Brand: ShanChun® Carbon

Fast delivery | Competitive price | mailto:info@shanchuncarbon.comConsistent quality