محصولات

الکترودهای با عملکرد بالا که برای کورههای قوس الکتریکی و کورههای ملاقه طراحی شدهاند و ذوب کارآمد و رسانایی پایدار را تضمین میکنند.

مواد آند بادوام برای الکترولیز آلومینیوم و سایر کاربردهای صنعتی که به عملکرد الکتریکی ثابت نیاز دارند.

افزودنیهای کربنی با خلوص بالا که برای تنظیم مقدار کربن و بهبود کیفیت فولاد و چدن استفاده میشوند.

Our Solutions

الکترودهای گرافیتی نقش مهمی در کورههای قوس الکتریکی دارند که به طور گسترده در صنعت فولاد استفاده میشوند. آنها مقادیر زیادی انرژی الکتریکی را هدایت میکنند تا قوسهای دمای بالا ایجاد کنند، قراضه فولاد و مواد اولیه را ذوب کرده و فولاد مذاب تولید کنند. این کاربرد امکان تولید فولاد کارآمد و انعطافپذیر را فراهم میکند، به ویژه در بازیافت قراضه فولاد.

کورههای ملاقهای از الکترودهای گرافیتی برای تصفیه فولاد مذاب پس از ذوب اولیه استفاده میکنند. آنها گرمای لازم را برای تنظیم ترکیب شیمیایی (افزودن آلیاژها)، یکنواخت کردن دما و حذف ناخالصیها فراهم میکنند. این فرآیند تضمین میکند که فولاد با استانداردهای دقیق کیفی برای کاربردهای مختلف از ساختوساز تا صنایع خودروسازی مطابقت داشته باشد.

در کورههای قوس زیرآب، الکترودهای گرافیتی برای تولید فروآلیاژها ضروری هستند. این الکترودها قوسهایی زیر سطح شارژ (مخلوطی از سنگ معدنها، احیاکنندهها و ...) ایجاد میکنند و حرارت شدیدی تولید میکنند تا فلزات را کاهش و آلیاژی کنند. این فرآیند برای تولید فروآلیاژهایی که خواص فولاد را مانند استحکام و مقاومت در برابر خوردگی بهبود میدهند، حیاتی است.

تأمین سالانه

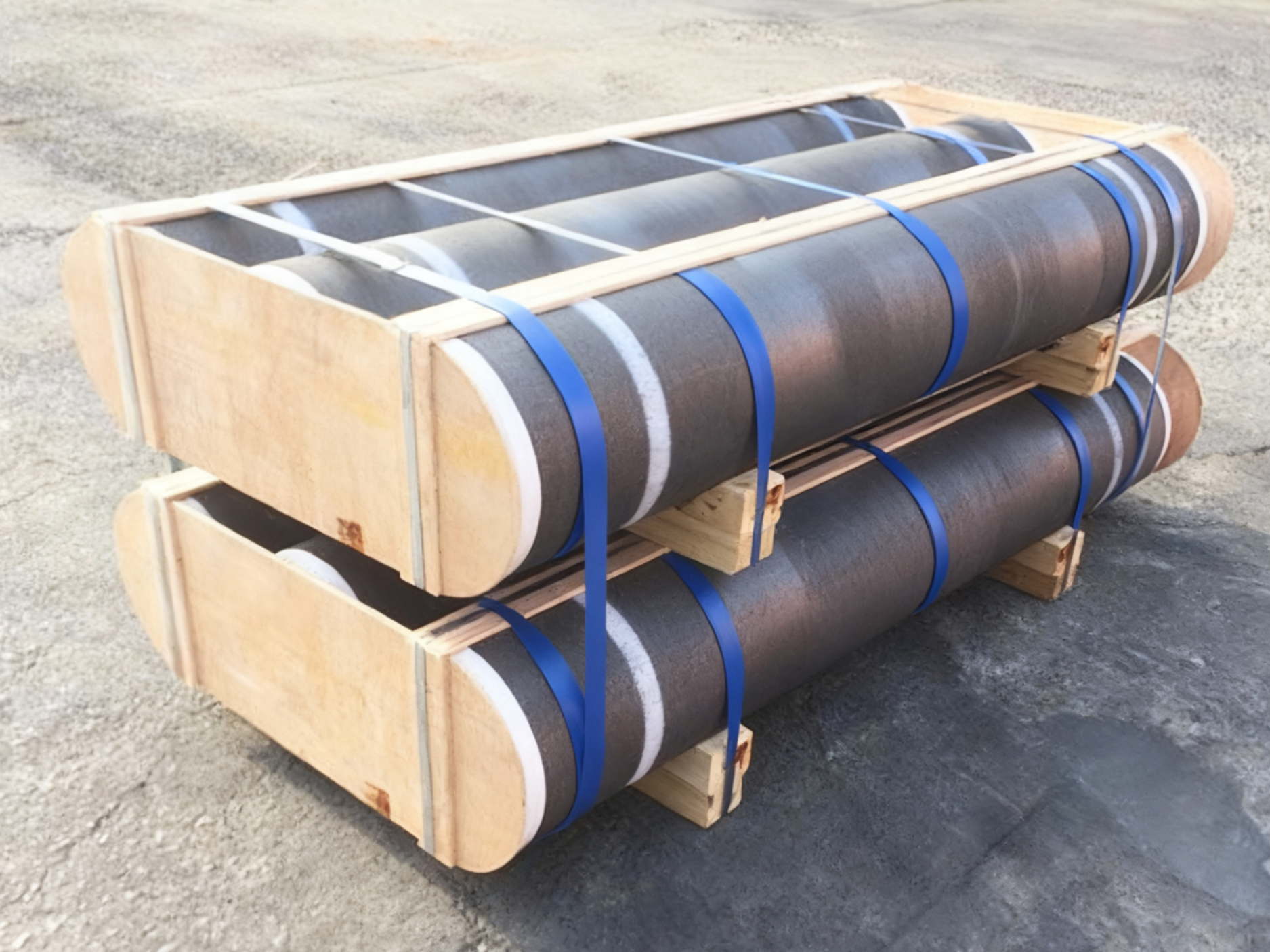

پشت هر محموله، تعهد ما به پایداری و عملکرد قرار دارد. شرکت Shanchun Carbon هر سال بیش از ۳۰,۰۰۰ تن مواد کربنی و گرافیتی با کیفیت بالا — از جمله الکترودهای گرافیتی، افزودنیهای کربنی، آندهای پختهشده و محصولات گرافیتی — عرضه میکند و پشتیبانی قابلاعتماد برای مشتریان فولاد، آلومینیوم و صنایع در سراسر جهان فراهم میسازد.

تأسیسات تولید

تأسیسات تولید مدرن ما مجهز به ماشینآلات پیشرفته و فناوری روز است که کیفیت برتر الکترودهای گرافیتی و افزودنیهای کربنی را تضمین میکند. با استفاده از میکسرها، اکسترودرها، کورههای دقیق و تجهیزات تست کارآمد، ما مقیاس، نوآوری و کنترل کیفی سختگیرانه را ترکیب کردهایم تا محصولات قابل اعتماد ارائه دهیم.