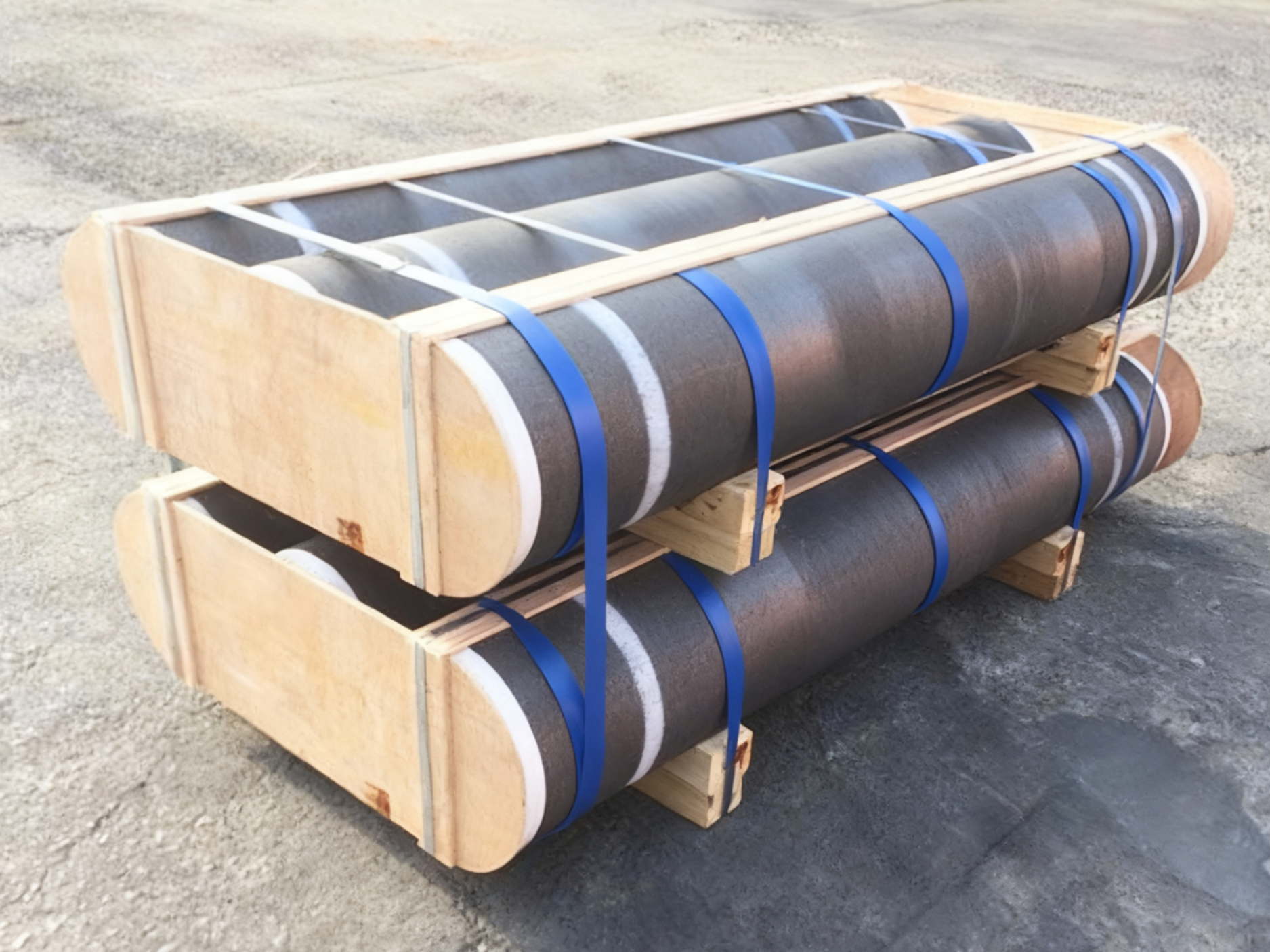

SiC Graphite Crucible for Melting Gold,Silver,Brass,Aluminium

What are SiC Graphite Crucibles?

Silicon Carbide Graphite Crucibles (SiC Crucibles) are premium quality crucibles being used at high temperatures which are suitable for metal melting, such as gold, silver, copper, brass, aluminum and refining other precious metals, base metals.

Advantages● SiC graphite material is more durable than clay graphite and can withstand temperatures up to 1800℃(3272°F), higher than clay graphite crucibles

● Durable foundry SiC graphite crucible is 3-8 times longer life than clay crucible.

● High-temperature resistant, suitable for high temperature metal melting,such as gold, silver, copper, brass, aluminum and more.

● Fit for all the furnaces such as Coke-Oven, Fuel Burner, Electric Furnace,etc

Technical Specification

| Standard Value | Typic Value | ||

| Refractoriness≥ | 1650℃ | Refractoriness≥ | 1665℃ |

| Apparent Porosity | 10~14% | Apparent Porosity | 10~14% |

| Bulk Density≥ | 1.9~2.1g/cm³ | Bulk Density≥ | 1.9~2.1g/cm³ |

| C≥ | 30~45% | C≥ | 30~45% |

| SiC≥ | 45% | SiC≥ | 48% |

Dimensions

Unit:mm

| Item | Top OD | Top ID | Height | Bottom OD |

| 80# | 295 | 250 | 365 | 170 |

| 100# | 340 | 280 | 365 | 200 |

| 120# | 340 | 285 | 390 | 170 |

| 150# | 370 | 310 | 452 | 150 |

| 200# | 400 | 345 | 510 | 190 |

| 250# | 445 | 380 | 565 | 220 |

| 300-1# | 460 | 390 | 595 | 240 |

| 300-2# | 530 | 470 | 530 | 340 |

| 350# | 480 | 410 | 633 | 260 |

| 370# | 530 | 470 | 570 | 340 |

| 400# | 520 | 455 | 665 | 250 |

| 450# | 520 | 460 | 765 | 282 |

| 463# | 590 | 522 | 600 | 340 |

| 500# | 535 | 465 | 725 | 280 |

| 505# | 540 | 465 | 780 | 290 |

| 530# | 590 | 525 | 630 | 340 |

| 593# | 620 | 545 | 610 | 360 |

| 600-1# | 560 | 470 | 810 | 410 |

| 600-2# | 590 | 527 | 650 | 340 |

| 650# | 620 | 550 | 630 | 360 |

| 790# | 620 | 555 | 690 | 360 |

| 800-1# | 630 | 550 | 720 | 290 |

| 800-2# | 650 | 570 | 650 | 330 |

| 802# | 620 | 558 | 710 | 360 |

| 910# | 710 | 610 | 600 | 440 |

| 950# | 710 | 612 | 660 | 450 |

| 1000-1# | 638 | 570 | 790 | 350 |

| 1000-2# | 616 | 538 | 820 | 420 |

| 1000-3# | 710 | 612 | 690 | 450 |

| 1050# | 715 | 615 | 730 | 450 |

| 1200# | 715 | 618 | 750 | 450 |

| 1300-1# | 650 | 570 | 1000 | 475 |

| 1300-2# | 720 | 620 | 800 | 450 |

| 1400# | 720 | 627 | 890 | 450 |

| 1550# | 780 | 680 | 750 | 400 |

| 1800# | 780 | 682 | 900 | 400 |

| 2100# | 855 | 775 | 835 | 350 |

| 2250# | 875 | 785 | 880 | 350 |

| 2600# | 900 | 790 | 1150 | 360 |

| 5000# | 1040 | 920 | 1320 | 550 |

| DZ1000 | 855 | 773 | 540 | 300 |

| DZ1550 | 775 | 680 | 750 | 450 |

| DZ1800 | 780 | 680 | 900 | 300 |

| DZ2300 | 880 | 775 | 1000 | |

| DZ2700 | 880 | 780 | 1170 | 330 |

| DL100 | 245 | 180 | 350 | |

| DL500-1 | 430 | 350 | 770 | 380 |

| DL500-2 | 480 | 420 | 653 | |

| DL1000 | 510 | 440 | 910 | 400 |