Petroleum coke

What is Petroleum Coke?

Petroleum coke is a combustible solid product derived from the coking process of residual oil and petroleum asphalt during petroleum processing. As a typical representative of graphitizable carbon, it is black and porous, with carbon being the dominant element and extremely low impurity content. Thus, it plays a vital role in various industrial fields such as metallurgy and chemical engineering, and is also the core raw material for the production of various graphite products.

Classification Methods of Petroleum Coke

Petroleum coke can be classified from different perspectives, with the following four common categories:

1. Classification by Coking Process

Based on the coking methods used in production, petroleum coke can be divided into open-hearth coke, kettle coke, delayed coke, and fluid coke. Among them, open-hearth coke and kettle coke have basically withdrawn from the mainstream market due to process limitations. Currently, the mainstream industrial products at home and abroad are delayed coke, accompanied by a small amount of fluid coke.

2. Classification by Heat Treatment Temperature

Divided by heat treatment temperature, petroleum coke can be categorized into green coke and calcined coke:

- Green coke is directly produced by delayed coking (or other coking processes), characterized by high volatile content and low mechanical strength;

- Calcined coke is the product of green coke after high-temperature calcination, whose performance can be significantly improved through calcination.

3. Classification by Sulfur Content

According to the level of sulfur content, petroleum coke can be classified into high-sulfur coke, medium-sulfur coke, and low-sulfur coke. This classification is of great guiding significance for the selection of application scenarios—low-sulfur coke, with fewer impurities, is more suitable for fields requiring high raw material purity.

4. Classification by Appearance, Structure, and Performance

Based on differences in appearance, internal structure, and performance, petroleum coke can be divided into three types: sponge coke, honeycomb coke, and needle coke. Each has distinct characteristics and applications:

- Sponge coke: Produced by coking residual oil with high content of colloid and asphaltene, it has a sponge-like appearance, relatively high impurity content, and is filled with small pores with thin pore walls. After graphitization, the artificial graphite made from it has high linear expansion coefficient and resistivity, so it is not suitable for the production of high-quality graphite products.

- Honeycomb coke: Made from residual oil with medium content of colloid and asphaltene, it has uniformly distributed internal small pores, showing a clear honeycomb structure, and its physical and mechanical properties are significantly better than those of sponge coke. This type of petroleum coke can be used as raw material for the production of RP graphite electrodes, carbon products for electrolytic aluminum, or electro-carbon products.

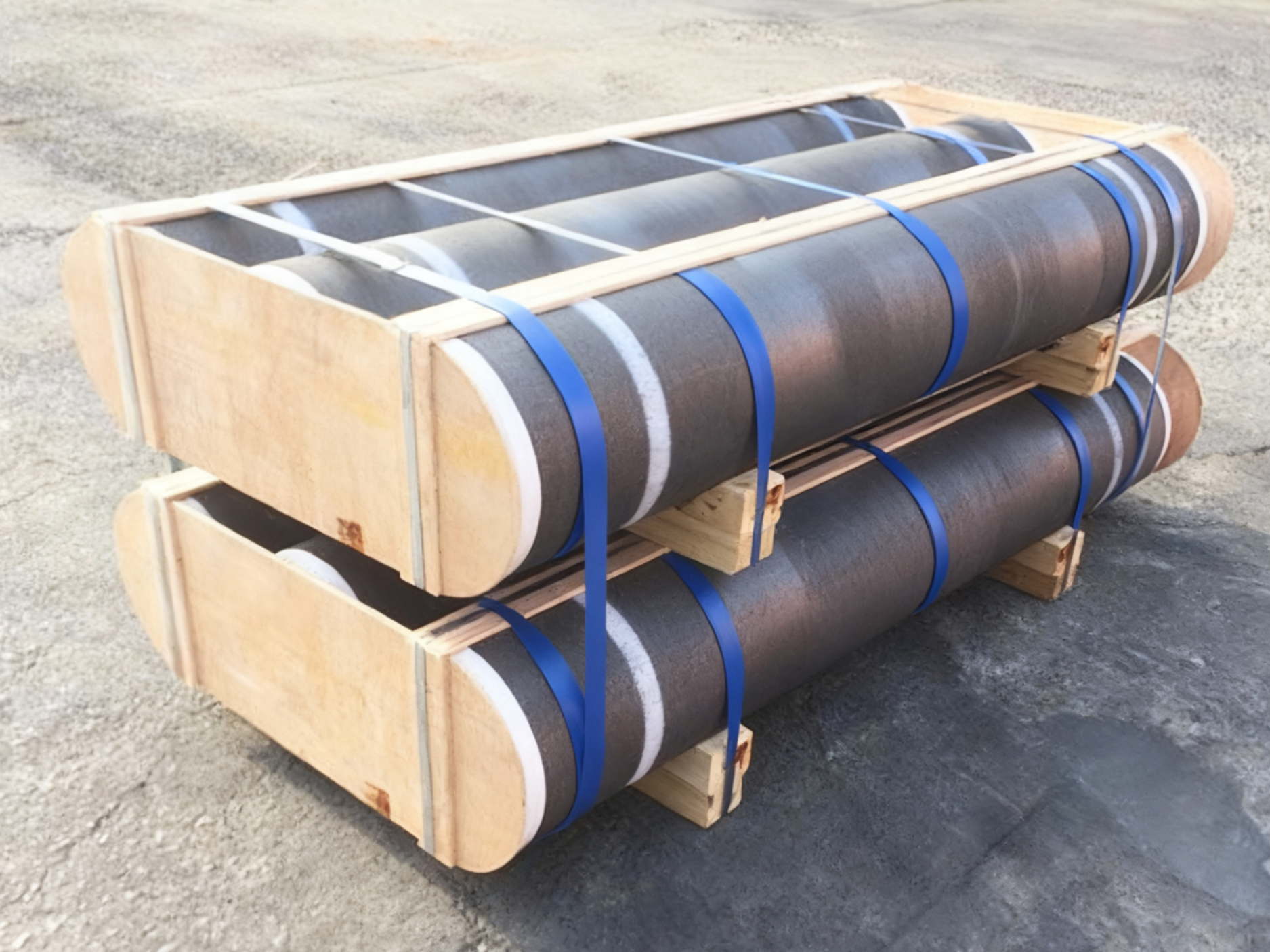

- Needle coke: Produced by coking high-quality residual oil with high aromatic content, low colloid and asphaltene content, low sulfur, and low ash. It has obvious stripes on the surface, with internal voids arranged in a directional manner as slender elliptical shapes, and breaks into slender particles. After graphitization, the artificial graphite obtained has low linear expansion coefficient and resistivity, making it a key raw material for the production of HP graphite electrodes and UHP graphite electrodes.

Through the systematic sorting of petroleum coke classifications, it is easy to see that its performance is closely related to raw material characteristics and production processes. Accurate classification provides a scientific basis for raw material selection in different industrial scenarios, helping related industries achieve efficient production and product quality improvement.

The Versatile Applications of Petroleum Coke: From Green Coke to Calcined Coke

Petroleum coke boasts a wide range of applications, spanning from electrolytic aluminum production to metallurgy and fuel. Its primary uses include serving as a key component in pre-baked anodes and anode pastes for electrolytic aluminum, as a carbon additive in the carbon industry, and in manufacturing graphite electrodes, industrial silicon for smelting, and even as a fuel source.

When it comes to producing graphite electrodes for steelmaking or anode pastes (molten electrodes) for aluminum and magnesium production, green petroleum coke must undergo calcination to meet stringent requirements. Typically conducted at around 1300°C, this process aims to remove volatile components as much as possible. Doing so reduces the hydrogen content in petroleum coke derivatives, enhances the graphitization degree of the coke, and consequently improves the high-temperature strength, heat resistance, and electrical conductivity of graphite electrodes.

Calcined coke finds extensive use in manufacturing graphite electrodes, carbon paste products, carborundum, food-grade phosphorus, metallurgy, and calcium carbide—with graphite electrodes being its most prevalent application.

Green coke, on the other hand, can be directly utilized without calcination. It acts as the main ingredient in calcium carbide production, and is used to make silicon carbide and boron carbide, which serve as abrasive materials. Additionally, it functions as coke for blast furnaces in metallurgy, as carbon bricks for blast furnace linings, and as dense coke in casting processes.

This versatility underscores petroleum coke’s indispensable role across diverse industrial sectors, where its properties—whether in raw or calcined form—are harnessed to drive efficiency and performance.