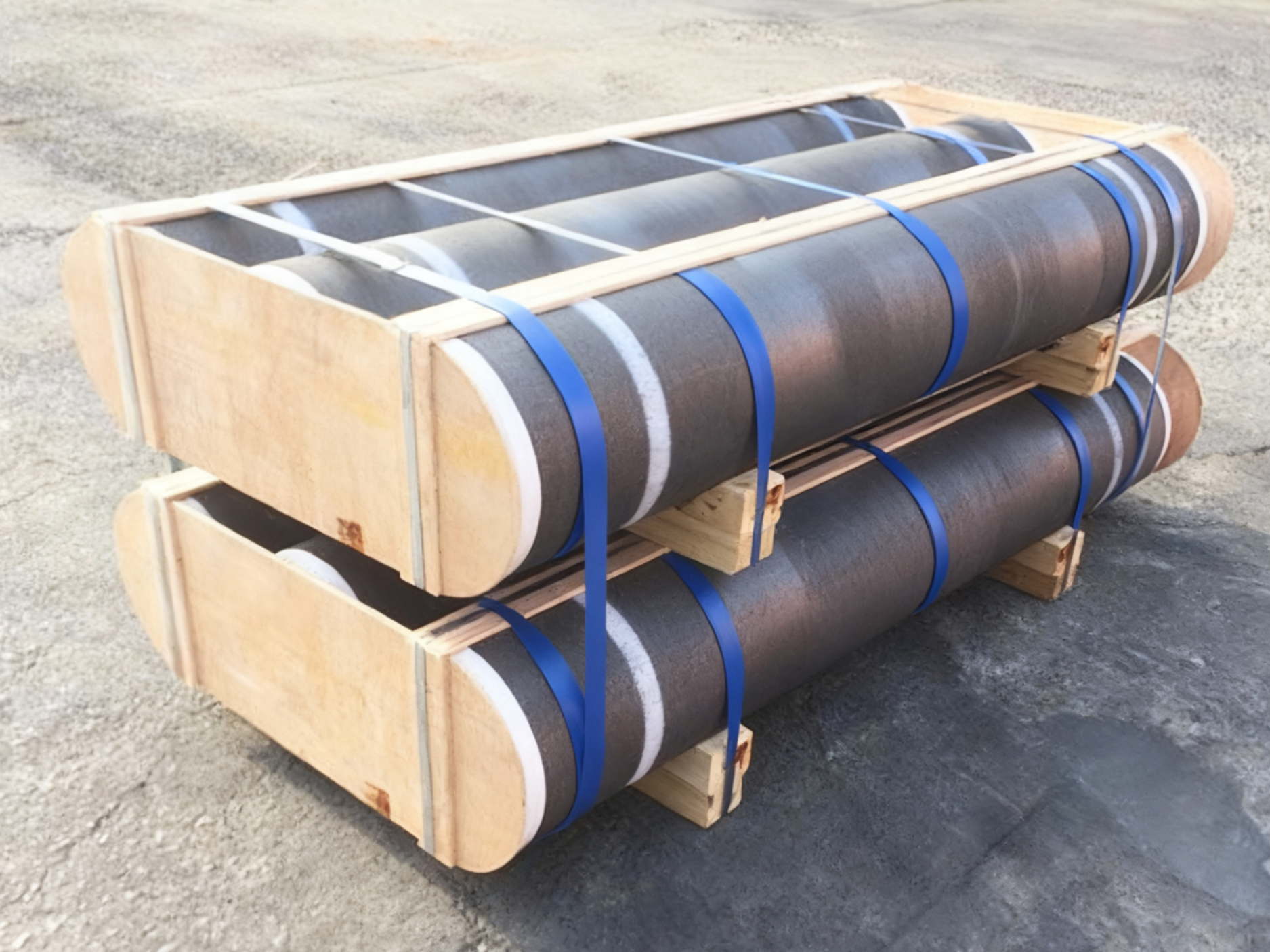

HP 200mm Graphite Electrode

- HP 200 Graphite Electrodes and Nipples are designed for ultra-high power electric arc furnaces (EAF) and ladle refining (LF) applications.

Graphite electrode is one of the most important metallurgical products, mainly used as conductive material in electric arc furnace metallurgy production. HP graphite electrode is mainly used for ultra high power electric arc furnaces, ladle furnace with the current density range of 18-25 A/cm2.

Graphite electrode Dimension

● Nominal Diameter: 200 (min 200mm, max 205mm)

● Nominal Length: 1800 mm (+100mm,-100mm)

● Nipple: 122 T4N

● Nipple Diameter: 122.24 mm

● Nipple Length: 177.8 mm

HP200mm Graphite Electrode Physical and Chemical Parameters

| Index | Unit | YB/T4090 Industry Standard | |

| Typical Value | |||

| LSR≤ | Electrode | μΩ.M | 5.0-7.5 |

| Nipple | 5.0 max | ||

| Flexural Strength ≥ | Electrode | Mpa | 6.0-8.5 |

| Nipple | 12.5-18.0 | ||

| Elastic Modulus ≤ | Electrode | Gpa | 6.5-10.0 |

| Nipple | 11.5-16.5 | ||

| Bulk Density ≥ | Electrode | g/cm³ | 1.60-1.72 |

| Nipple | 1.70 | ||

| CTE ≤ | Electrode | 10-6/ ℃ | 1.6-2.0 |

| Nipple | 1.2-1.5 | ||

| Ash ≤ | % | 0.3 | |

| Current Carrying Capacity | A | LF 5500-9000 | |

Advantage

● Anti-oxidation treatment for longevity

● High-purity, high-density, strong chemical stability

● Resistant to cracking & spalling

● High resistance to oxidation and thermal shock

● High mechanical strength, low electrical resistance

● High machining accuracy, good surface finishing