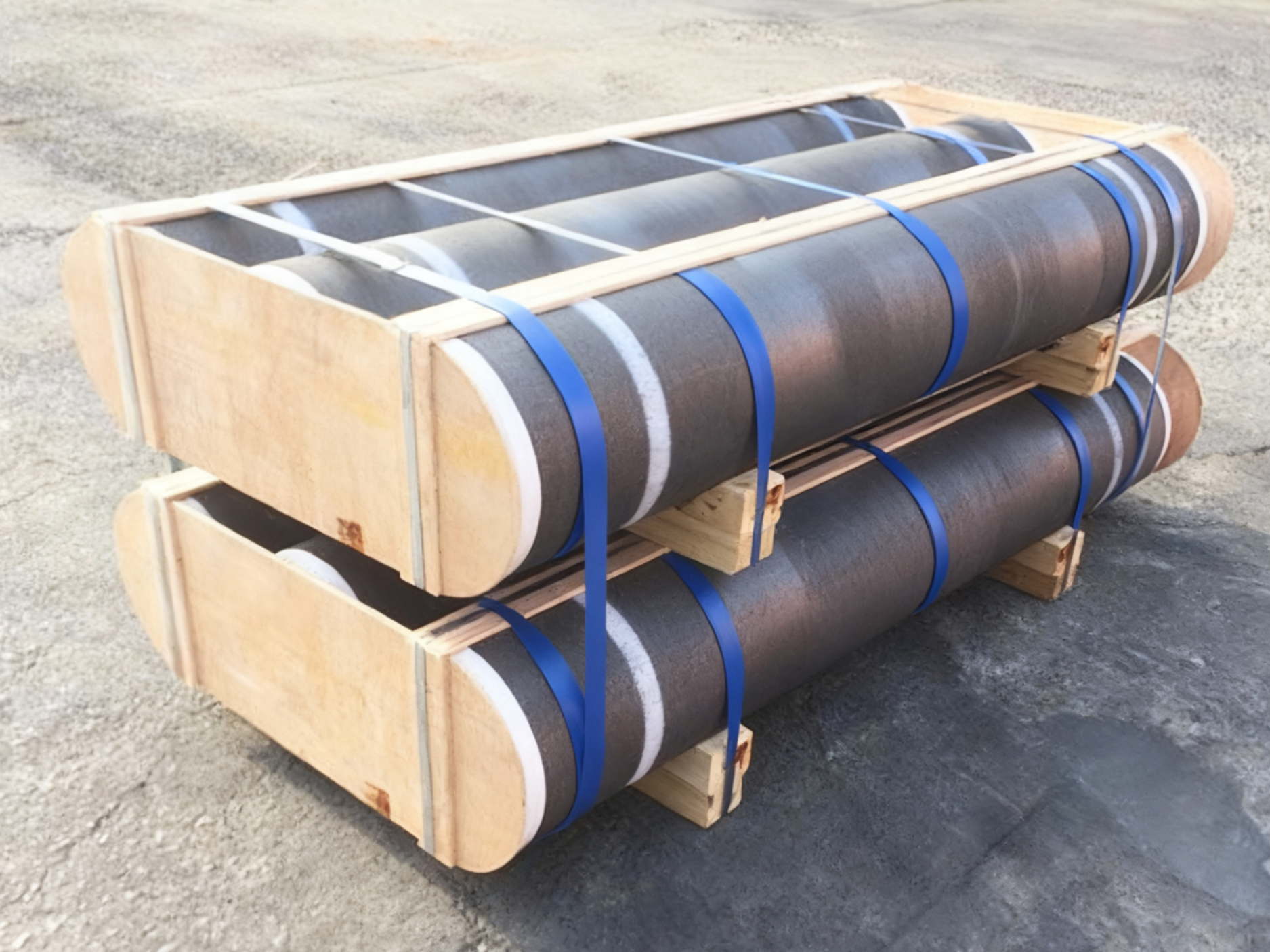

Graphite Pipes

- 1shanchuncarbon

Graphite pipe are made of fine grain graphite materials and are available in various sizes. It is most frequently used for Aluminum degassing in the metal manufacturing industry, and the highest temperature of the graphite pipe can reach 3000℃. It’s also widely used in a heat source or heat radiation of high-temperature environments and other various mechanical friction conditions.

Production Process

Raw material →Medium crushing →Milling →Screening →Dosing→Vibrated →Molding →Impregnation →Baking →Graphitization

Technical Specification of Graphite Material

Graphite tubes can be manufactured and to select graphite materials as your requirements or working conditions.

| Type | Bulk Density(g/cm3) | ResistivityμΩ.m | Thermal conductivityW/(m) | Thermal expansion coefficient(x10-6/℃) | ShoreHardnessHSD | Flexural strengthMpa | Compressive strengthMpa | Porosity%≤ | Granularityμm |

| Moled Graphite | 1.8 | 8-11 | 125 | 5.46 | 45 | 43 | 75 | 17 | 13-15 |

| 1.85 | 8-10 | 142 | 4.75 | 48 | 46 | 90 | 13 | 13-15 | |

| IsostaticGraphite | 1.9 | 8-9 | 140 | 5.1 | 58 | 59 | 98 | 11 | 8-10 |

| 1.95 | 11-13 | 87 | 5.64 | 76 | 68 | 145 | 11 | 8-10 | |

| 1.68 | 13 | – | – | – | 25 | 50 | – | – | |

| 1.82 | 14.2 | – | – | 68 | 58 | 118 | 12 | – | |

| 1.85 | 13.5 | – | – | 67 | 65 | 135 | 11 | – | |

| Coarse grain | 1.6 | 9-12 | – | – | ≥25 | ≥13 | ≥22 | – | 0-2 0.8 |

| Fine grain | 1.72 | 8-11 | – | – | ≥30 | ≥17 | ≥30 | – | 0-2 0.8 |

| Size available OD*ID*L(mm) | |||||

| 20*10*50 | 20*10*100 | 20*10*200 | 20*10*400 | 30*20*50 | 30*20*100 |

| 30*20*200 | 30*20*400 | 40*20*50 | 40*20*100 | 40*20*200 | 40*20*400 |

| 40*30*50 | 40*30*100 | 40*30*200 | 40*30*400 | 50*40*50 | 50*40*100 |

| 50*40*200 | 50*40*400 | ||||

Advantages

The advantages of the graphite tubes are as following:

Fine particles.

High temperature resistance to 3000 ℃ .

Anti-oxidation, long working life time.

Excellent thermal and electrical conductivity.

High Density and Good flexural strength.

Resistance to chemical erosion and thermal shock.

Application

1. Aluminum degassing tube.

2.Copper smelting mold.

3.Channel for high temperature molten metals.

4.Heating tube for various industrial furnaces.

5.grounded electrodes or sacrificial anodes.

6. Foundry,casting, glass, chemical industries.