UHP 450mm Graphite Electrodes

- 1shanchuncarbon

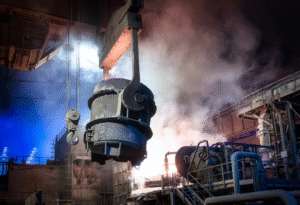

Ultra-High Power (UHP) graphite electrodes, such as the UHP 450mm Graphite Electrodes, are critical components in electric arc furnaces (EAF) and ladle furnaces (LF). Their high density, low resistivity, and excellent thermal stability allow for efficient and consistent steel melting, reducing energy consumption while improving electrode longevity.

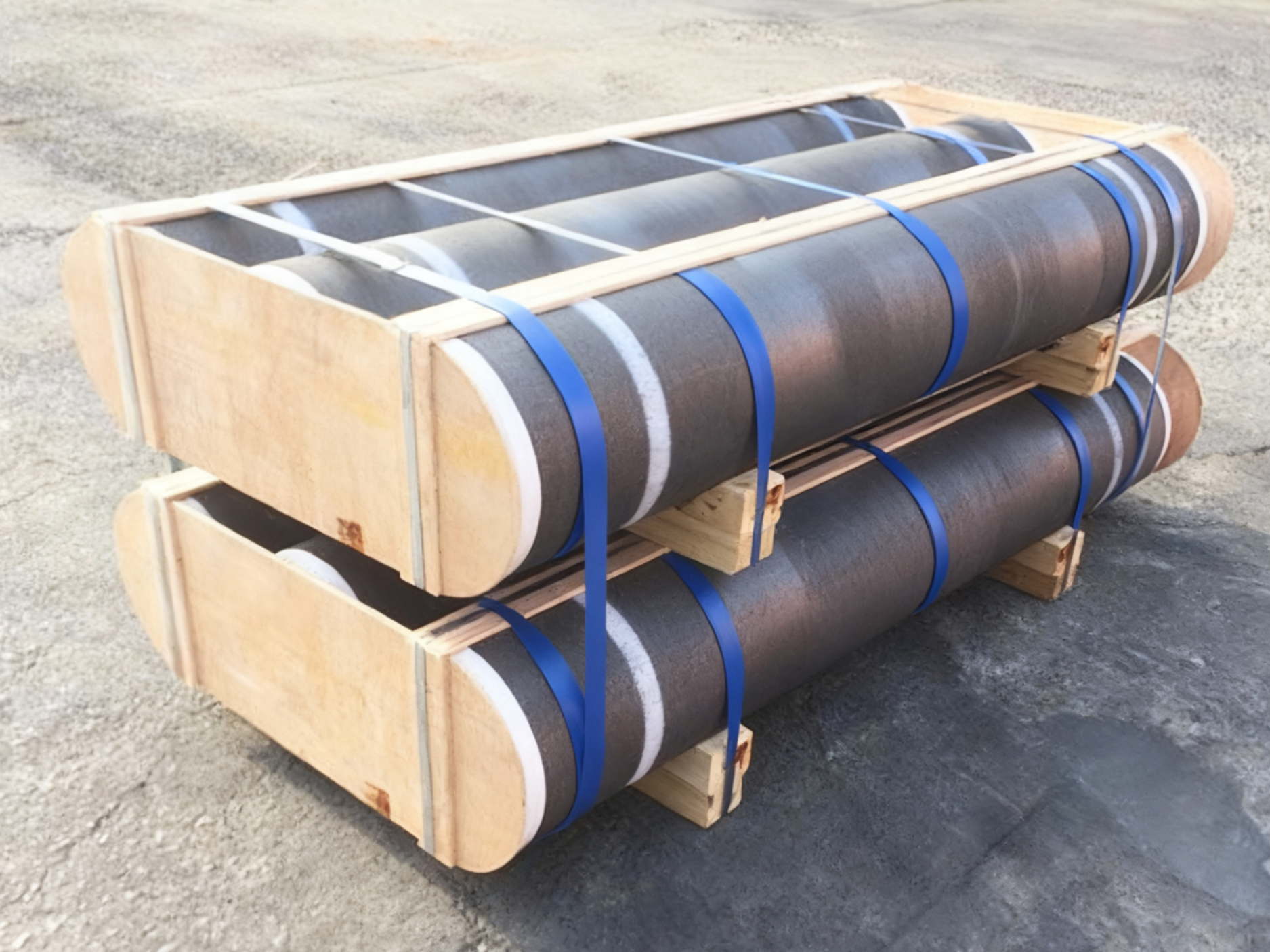

The combination of UHP450mm graphite electrodes with high-quality graphite electrode nipples ensures consistent electrical performance, reduced maintenance, and enhanced furnace safety.

Applications of UHP 450 mm Graphite Electrodes

- Electric Arc Furnace (EAF): Provides stable arcs and high conductivity for efficient steel melting.

- Ladle Furnace (LF): Ensures uniform heating and chemical refining in secondary steelmaking.

- Other High-Temperature Metallurgical Processes: Suitable for any process requiring high-current graphite electrodes with thermal and mechanical reliability.

Graphite electrode Dimension

● Nominal Diameter: 457mm (min 454mm, max 460mm)

● Nominal Length: 1800/2100/2400 mm (+100mm,-100mm)

● Nipple: 241 4TPI Long Type

● Nipple Diameter: 241.3 mm

● Nipple Length: 355.6 mm

Physical and Chemical Parameters of UHP 450mm Graphite Electrodes

| Item | Unit | YB/T4090 Industry Standard | |

| Typical Value | |||

| LSR≤ | Electrode | μΩ.M | 6.0 |

| Nipple | 5.0 | ||

| Flexural Strength ≥ | Electrode | Mpa | 10.0 |

| Nipple | 18.0 | ||

| Elastic Modulus ≤ | Electrode | Gpa | 14.0 |

| Nipple | 18.0 | ||

| Bulk Density ≥ | Electrode | g/cm³ | 1.66 |

| Nipple | 1.75 | ||

| CTE ≤ | Electrode | 10-6/ ℃ | 1.5 |

| Nipple | 1.4 | ||

| Ash ≤ | % | 0.3 | |

| Current Carrying Capacity | A | 34000-55000 | |

Advantage

● Withstand large currents, high discharge rate

● Good dimension stability, not easy to deform

● Resistant to cracking & spalling

● High resistance to oxidation and thermal shock

● High mechanical strength, low electrical resistance

● High machining accuracy, good surface finishing