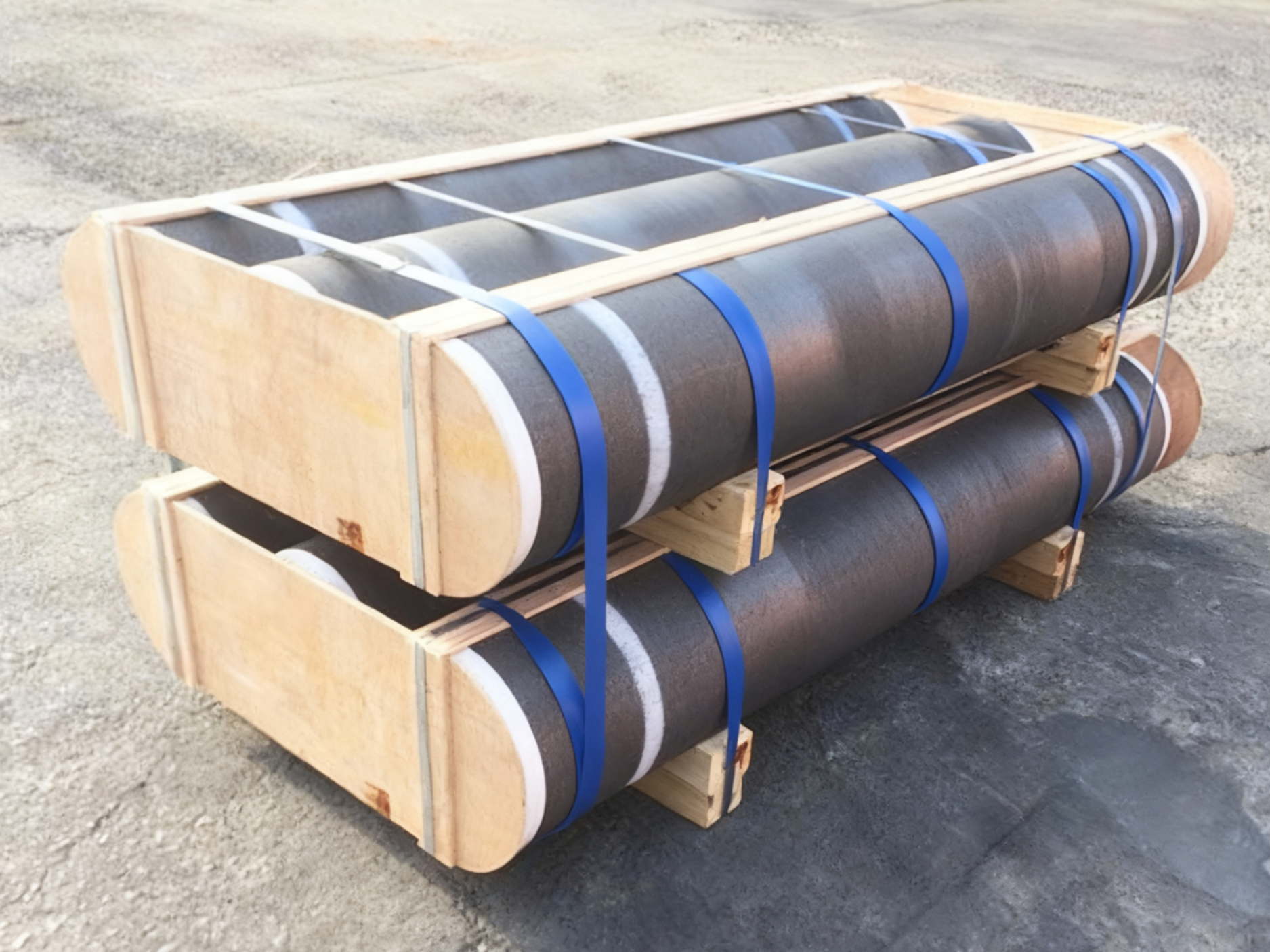

UHP 550mm Graphite Electrodes

- 1shanchuncarbon

ShanChun Carbon®’s UHP 550mm Graphite Electrodes are engineered for high-demand steelmaking and metallurgical processes. As part of our UHP Graphite Electrode range, this 550mm diameter size delivers superior conductivity, mechanical strength, and thermal stability, ensuring consistent performance in Electric Arc Furnaces (EAF) and Ladle Furnaces (LF).

Graphite electrode Dimension

● Nominal Diameter: 550mm (min 556mm, max 562mm)

● Nominal Length: 2400 mm (+75mm,-125mm)

● Nipple: 298T4N

● Nipple Diameter: 298.45 mm

● Nipple Length: 355.6 mm

● Typical Weight: Electrodes and Nipple Approx.1005 kg

Key Features

- High Electrical Conductivity: Facilitates efficient arc formation and energy transfer in high-temperature furnaces.

- Excellent Mechanical Strength: Minimizes breakage and reduces downtime during operation.

- Thermal Stability: Withstands extreme thermal shocks and prolonged furnace cycles.

- Precision Manufacturing: Tight dimensional tolerances ensure seamless installation with compatible Graphite Nipples.

Physical and Chemical Parameters of UHP550mm Graphite Electrode

| Index | Unit | YB/T4090 Industry Standard | |

| Typical Value | |||

| LSR≤ | Electrode | μΩ.M | 4.5-5.8 |

| Nipple | 3.4-4.5 | ||

| Flexural Strength ≥ | Electrode | Mpa | 6.0-8.0 |

| Nipple | 15.0-24.0 | ||

| Elastic Modulus ≤ | Electrode | Gpa | 9.0-16.0 |

| Nipple | 12.0-18.0 | ||

| Bulk Density ≥ | Electrode | g/cm³ | 1.65-1.80 |

| Nipple | 1.76-1.86 | ||

| CTE ≤ | Electrode | 10-6/ ℃ | 1.1 |

| Nipple | 0.9 | ||

| Ash ≤ | % | 0.3 | |

| Current Carrying Capacity | A | EAF 45000-68000LF 45000-69000 | |

SHANCHUNCARBON provides a complete lineup of graphite electrodes to suit different operational needs:

- UHP Graphite Electrodes – Ultra High Power, for the most demanding steelmaking operations.

- HP Graphite Electrodes – High Power, for standard high-performance furnaces.

- RP Graphite Electrodes – Regular Power, ideal for conventional applications.

All series are compatible with our Graphite Nipples, ensuring a reliable and easy-to-install electrode system.

Why Choose SHANCHUNCARBON?

At SHANCHUNCARBON, we combine decades of expertise in carbon materials with advanced production technologies to deliver electrodes that meet global standards. Our UHP graphite electrodes are:

- Manufactured with high-purity raw materials.

- Tested under rigorous quality control to ensure uniform density and conductivity.

- Supported with technical guidance for optimal furnace performance.

Learn More

For detailed knowledge about graphite electrodes and industry standards, you can refer to the World Steel Association or explore our full Graphite Electrode Solutions at SHANCHUNCARBON.